Silicone molds

- Home

- Rapid Prototyping

- Silicone molds

Polyurethane resins, silicone rubbers

Prototype making with Silicone Molds is a micro-manufacturing technique called “soft tooling” since the mold is made of precisely soft material.

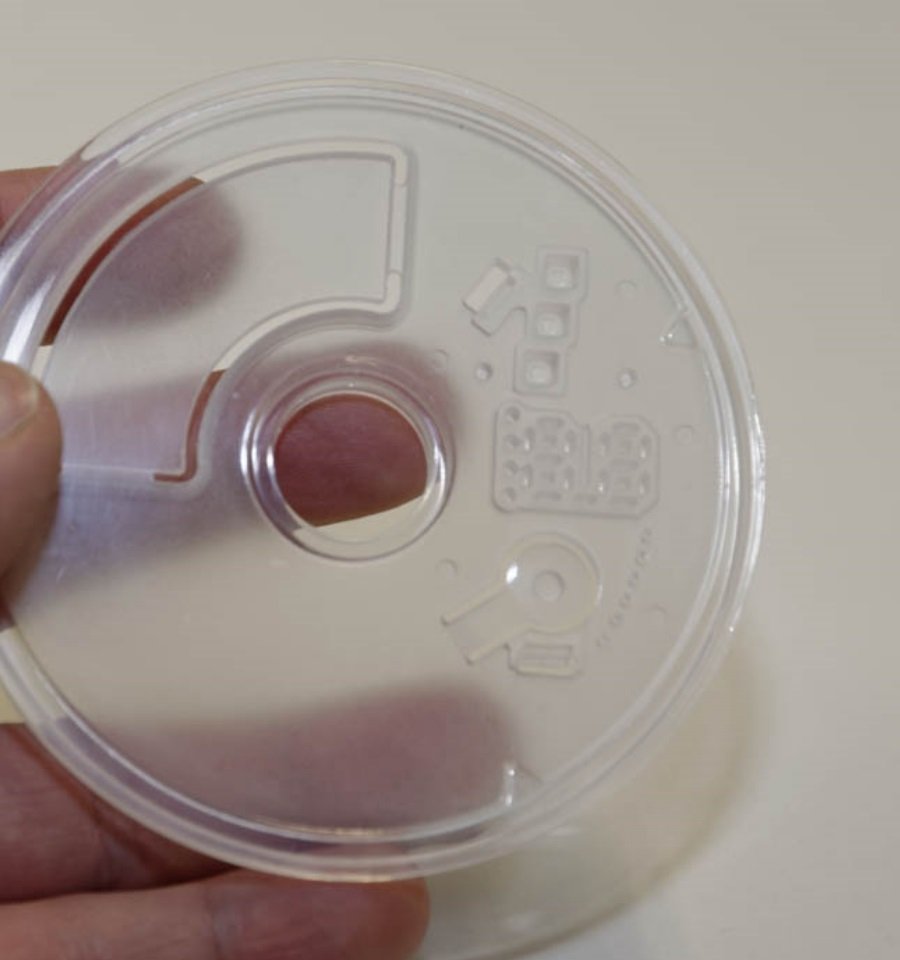

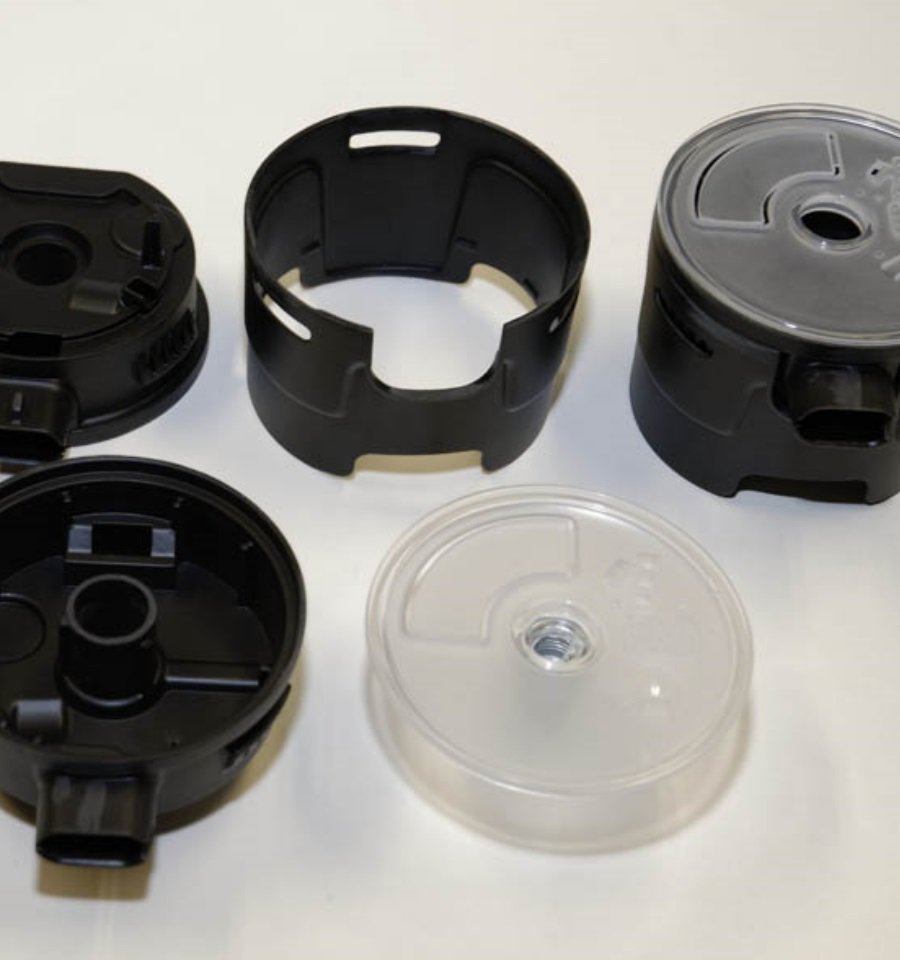

This technique is essentially based on making a silicone mold from a “master” object. When the silicone cures around the master it makes it possible to remove the master, which leaves a hollow impression making in essence a mold that can be filled with casting resins. The most commonly used casting resins are two-component polyurethanes that are formulated to resemble in technical characteristics the most popular production materials, which can be either rigid plastics (opaque or transparent) or silicone rubbers.

Polymer castings are made in a vacuum chamber that serves to eliminate bubble inclusions.

A silicone mold precisely because of the elasticity of the matrix is ideal for making those complex figures, full of details and small undercuts that are “solved” by taking advantage of the elasticity of the silicone matrix, that is, by forcing the ejection of the component that is somehow torn out of the silicone mold. Due to this aspect of mechanical stress as well as to chemical aggression a silicone mold usually has a service life of no more than 20-30 extractions (depending on the complexity of the figure and the aggressiveness of the resin). Silicone replica resins can be pre-pigmented giving rise to objects already colored as desired.

-

Simil PA

-

Simil PA-GF

-

ABS-like

-

Special materials with resistance to UV radiation

-

Special materials with high temperature resistance (>180°C)

-

Silicone rubbers

-

others upon request (subject to availability from Basf/DuPont).

-

Grids

-

Cappellotti

-

Knobs

-

Burners

-

Wok Supports

-

Bathtubs

-

Distributors

-

Shut-off valves

-

Control valves

-

Pump body

-

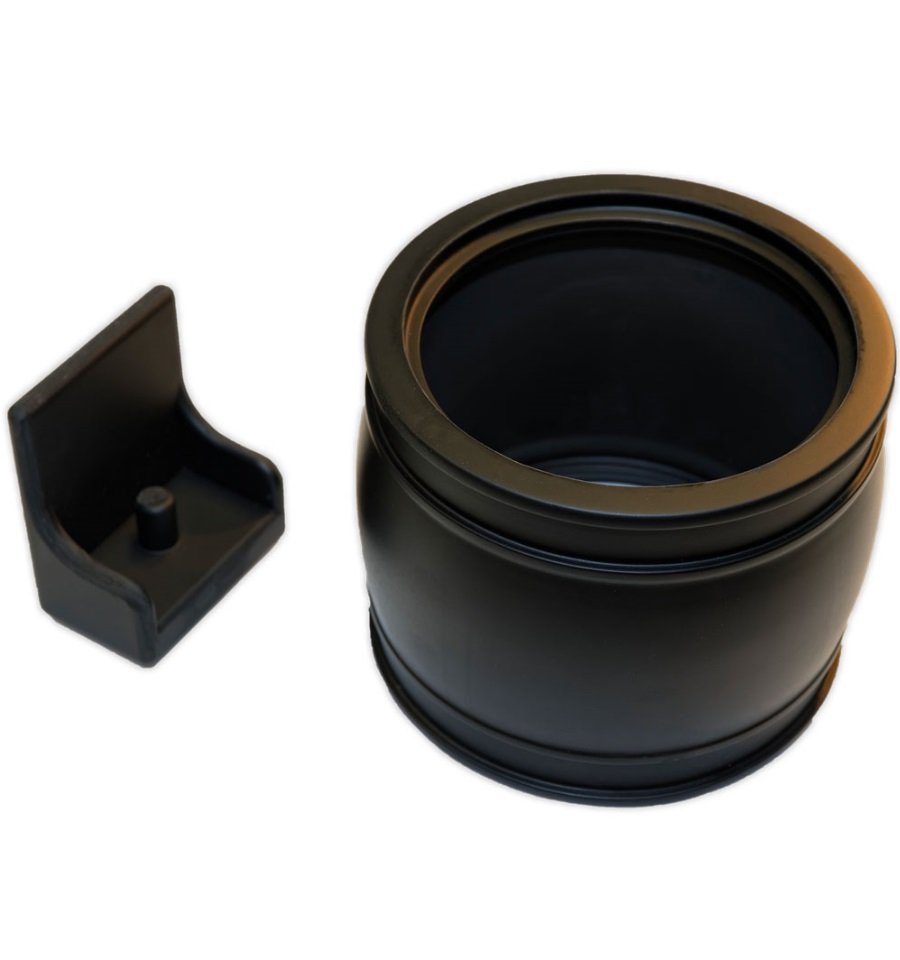

Carrier lantern

-

Mouthpieces

-

Valves

-

Shredders

-

Open Impellers

-

Closed Impellers

-

Single-channel impellers

-

Speakers

-

Circulators

-

Supports

-

Engine shields

-

Inverter boxes

-

Carcasses

-

Finned masses

-

Streetlights

-

Racing Components

-

Aluminum frames

-

Engine cylinders

-

Motor heads

-

Brake calipers

-

Clutch Crankcase

-

Engine crankcase

-

Gearboxes

-

Frame elements

-

Forks